Overview

Commissioned by Denki Kagaku Systems Co., Ltd.

Screen UI for automatic developer solution monitoring system used in semiconductor manufacturing facilities was redesigned.

Information structure and color rules were reorganized to create consistent interface that clearly draws attention to notices and warnings.

Icons were added to improve recognition of control functions, aiming for screen design that reduces operational confusion and supports safe, intuitive operation.

Background

Automatic developer solution management systems used in printed circuit board manufacturing processes function as HMIs handling multiple parameters—such as concentration, temperature, and flow rate—on continuous basis.

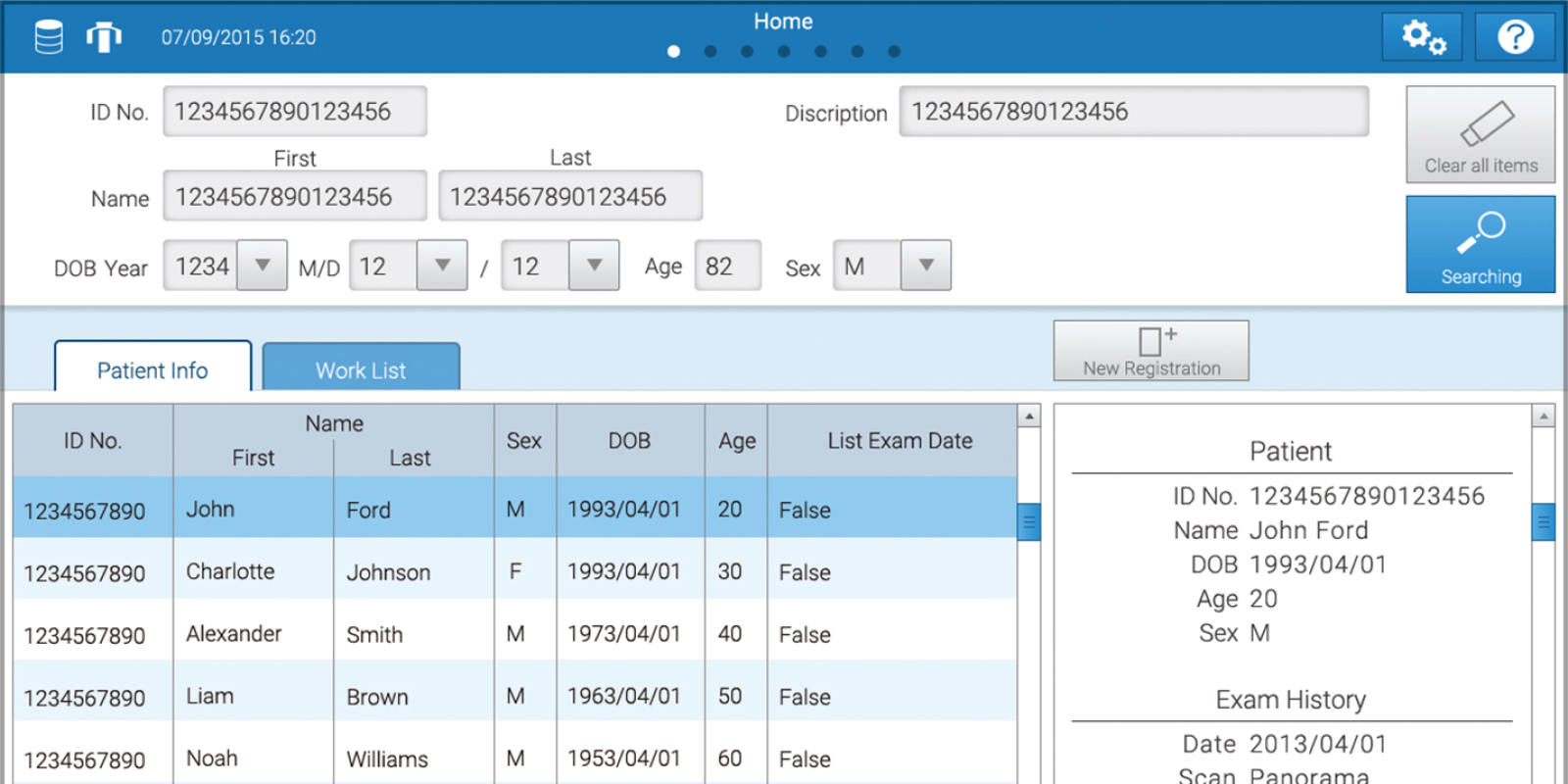

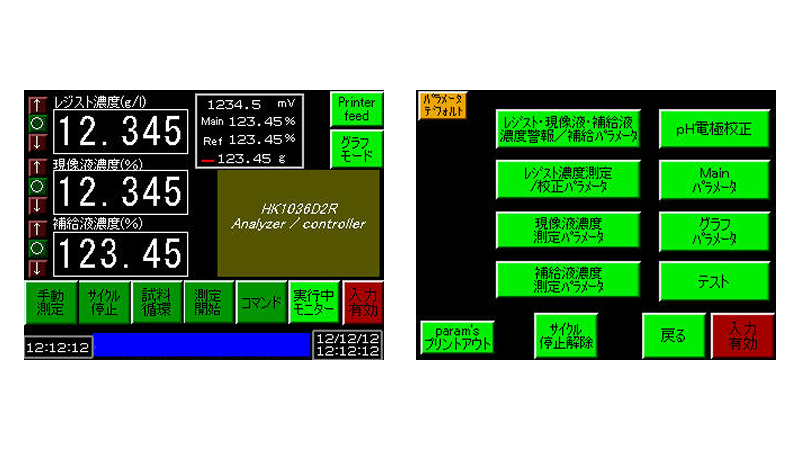

In conventional, text-heavy interfaces, distinctions between status priority and operation availability were not clearly communicated.

UI capable of supporting safe and rapid decision-making by on-site operators was therefore required.

Proposal

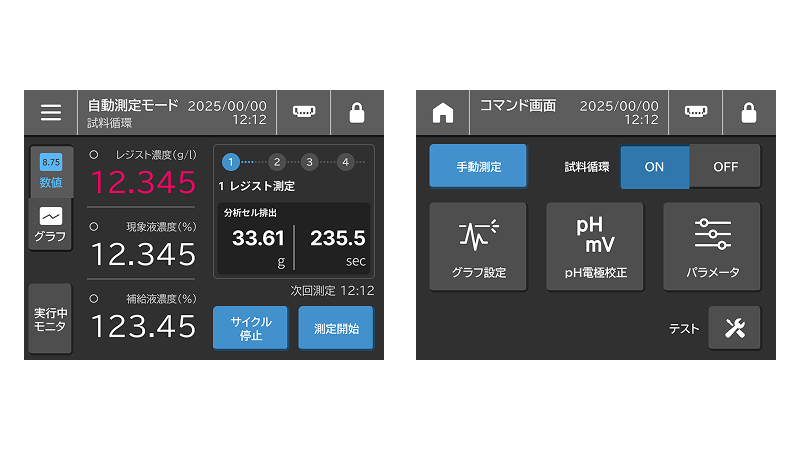

1. Key Color System

Key states—such as Normal (e.g., Neutral / Primary) and Warning (Danger)—were systematized to enable immediate recognition of status priority.

To avoid reliance on color alone, dual coding using shapes and labels was applied.

2. Icon Integration

Values, graphs, screen lock states, and menus were visualized through icons.

This approach reduces dependency on text length and supports multilingual environments.

3. Differentiation Between Information Display and Controls

Controls were designed with dimensional cues—filled surfaces, depth, and press shadows—while information displays were kept flat with outline-only styling.

Disabled states were consistently expressed through opacity, providing clear visual affordances.

4. Front-End Implementation Using VT Studio

Tap areas were optimized for low-spec hardware and gloved operation, ensuring reliable usability in manufacturing environments.

Outcome

At the exhibition where the system was unveiled for the first time, we received positive feedback that it attracted strong interest from other companies.

Although this was our first project involving semiconductor manufacturing equipment, gaining deep understanding of the operational environment enabled us to take on new field, making it valuable experience for our team.

We continue to work closely with clients—especially those commissioning us for first time—by discussing implementation and workflow in detail and delivering design with care and confidence.